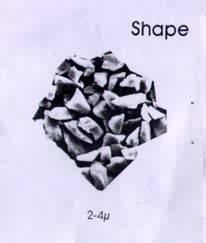

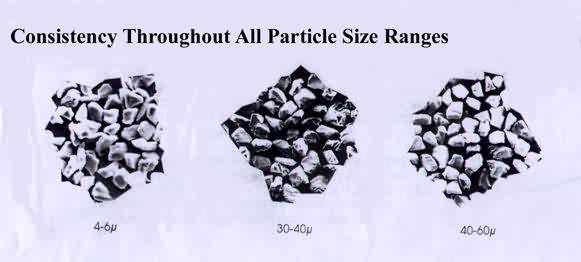

Shape Characteristics

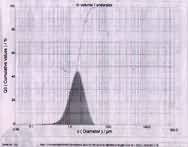

View Well Superabasive being a pioneer in the micron Superabrasive industry, has determined through years of experience working with process engineers and end-users, that the shape of monocrystalline micron powder plays a key role in the performance of quality products. View Well Superabasive produces FULL-BODIED ANGULAR crystals SLIGHTLY IRREGULAR in shape, in order to remove material more effectively from the workpiece. View Well Superabasive maintains a consistent crystal shape throughout its full spectrum of Superabrasive families and size offerings. Each crystal performs as an individual cutting tool which is not governed by its dimensional size. The SEM's clearly show View Well Superabasive's controlled shape consistency.

Full-bodied Angular Crystal Performance in Applications

1.Free Abrasive Machining

View Well Superabasive's crystal shapes result in immediate cutting action while providing a long and aggressive crystal life.

2.Resin and Metal Bonded Wheels

Full-bodied Angular crystals deliver immediate aggressive material removal rates and provide superior bonding qualities. The angular crystal shape allows particles to be retained in the bond longer and consumed more completely with diminished "POP-OUT" liability associated with rounded crystal shapes.

3.Electroplated Tools

Full-bodied angular crystals are perfectly suited for electroplated bonding applications. Each crystal performs as a cutting tool which is essential in the mechanics of electroplated tool life and quality.